Basalt yarn textile

Basalt Roving

Basalt Rebar

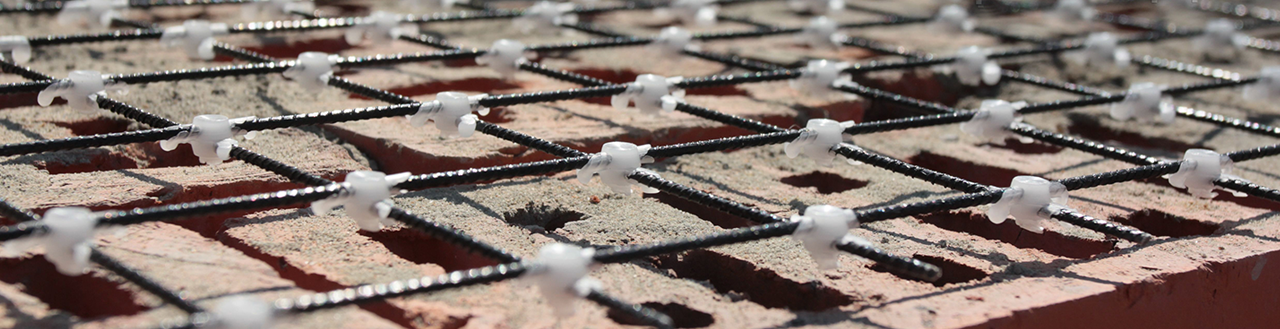

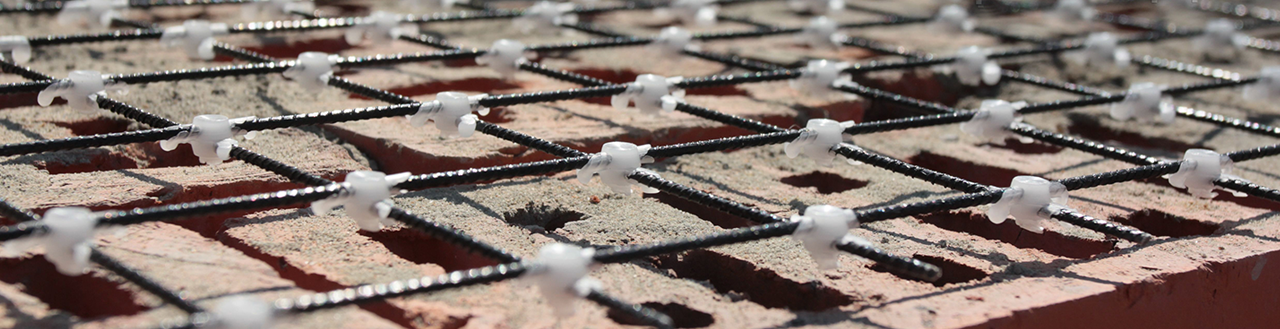

Reinforcing Mesh

Machines for the Production of Rebars and Reinforcing Meshes

Basalt yarn textile

Basalt Roving

Basalt Rebar

Reinforcing Mesh

Machines for the Production of Rebars and Reinforcing Meshes

Filament Winding

Basalt Yarn

Basalt yarn is manufactured by melting chopped basalt rocks in а furnace under the temperature of 15000°C. A large amount of iron oxide in basalt rocks gives the stone typical dark color and increases the homogenization and the temperature of crystallization. Concerning the viscosity, basalt yarn is steeper than fiberglass yarn.

Comparative Characteristics of Glass Fiber and Basalt Fiber

|

Features |

Basalt Fiber |

Glass Fiber |

|

Thermal Operation temperature, °C |

from-260 to +700 |

from -60 to + 460 |

|

Sintering temperature, °C |

1000 |

600 |

|

Coefficient of thermal conductivity, W / mK |

0,031 -0,038 |

0,034 – 0,04 |

|

Physical The diameter of filament, micron |

9-23 |

6-17 |

|

Tex (g/km) |

28-480 |

28-480 |

|

Density, kg / mz |

2600-2800 |

2540-2600 |

|

Modulus of elasticity, kg / mm2 |

9100-11000 |

to 7200 |

|

Durability after Thermal Treatment, % |

||

|

at 20 °C |

100 |

100 |

|

at 200 °C |

95 |

92 |

|

at 400 °C |

82 |

52 |

Types of Twisted Yarns

A single yarn twist - the most simple one, twisted in one direction.

Multitwisted yarn - two or more single yarns can be twisted together to form a thicker yarn.