Basalt yarn textile

Basalt Roving

Basalt Rebar

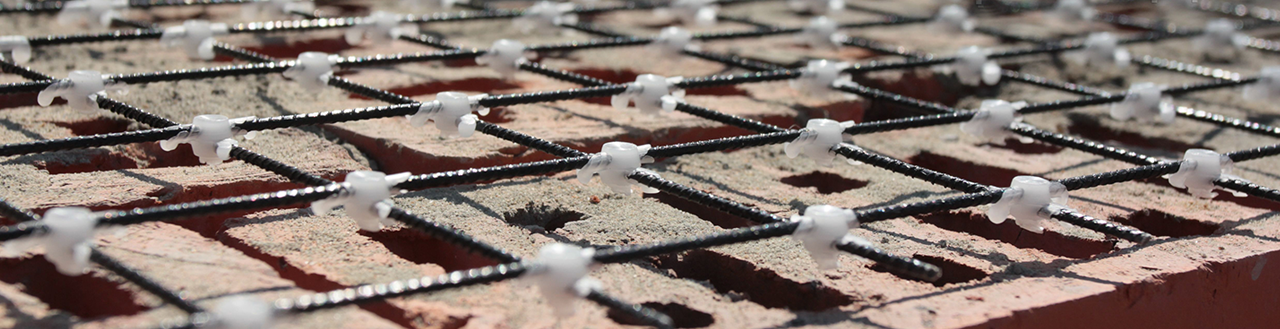

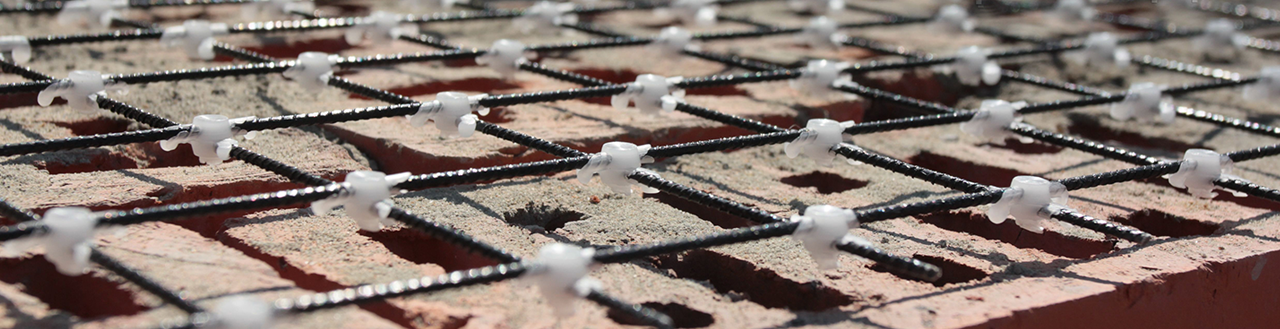

Reinforcing Mesh

Machines for the Production of Rebars and Reinforcing Meshes

Basalt yarn textile

Basalt Roving

Basalt Rebar

Reinforcing Mesh

Machines for the Production of Rebars and Reinforcing Meshes

BASALT ROVING

Basalt Roving – Assembled basalt roving consists of several strands, drawn at the facility for the production of continuous basalt fiber and then assembled together, at assembling machines.

Main Characteristics of Assembled Basalt Roving:

|

Type |

Indicators |

|

Material |

Basalt rock |

|

Roving structure |

Assembled |

|

Filament diameter, Micron |

8-22 |

|

Linear density, tex |

600-4800 |

|

Type of sizing |

Silan |

- Eco-friendliness;

- High durability;

- Corrosion resistance to aggressive environments;

- Sound absorption;

- Dielectric character;

- Resistance to ultraviolet radiation;

- High heat and moisture resistance.

Characteristics of Basalt Roving

- Color - dark-olive;

- Оdor – inodorous;

- Filament diameter - 8 – 22 µ;

- Tensile strength – not less 650 mN/Tex

- Tensile modulus in epoxy impregnated strand - 80 – 95 GPa

- Operation temperature - from -260 to +700 ° C;

- Elongation - 3.5%;

- Type of sizing - 4с;

- Sizing content – not more 1%;

- Bobbin type - cylindrical bobbin with internal or external unwinding;

- Bobbin weight – as customer requested;

- Standard packing - 72 bobbins in a pallet.